Prefabricated Hospitals Solutions

Prefabricated Hospitals Solutions

|

This is a very similar solution to commonly known prefabricated buildings. Difference comes from ModulTechnics expertise in hospital and accomodation environments and more importantly offering a turn-key solution with all the systems and equipments included. Prefabricated hospitals can be defined as prefabricated structures specifically designed and manufactured to provide modern medical services. These structures are prefabricated, prepared in separate sections, and transported to an existing site. |

|

|

|

Prefabricated hospitals offer numerous advantages. Firstly, they can be quickly erected on-site with minimal time and effort. Therefore, they are a preferred choice for emergencies and temporary healthcare facilities. Prefabricated hospitals have a modular structure. This allows them to be easily used to expand the capacity of existing healthcare centers or temporarily increase medical service delivery. Furthermore, specially designed with patient comfort in mind, prefabricated hospitals provide hygienic environments and are designed to ensure orderly placement of medical equipment. |

|

|

Production line includes:

|

|

|

|

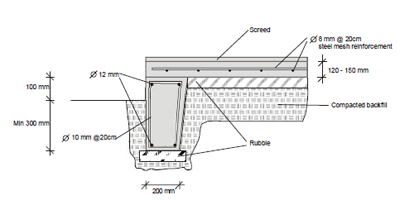

Concrete foundation will be prepared according to drawing designed by technical office. There will be adequate insulation under the foundation. An additional sulphate resistantlayer will be applied if necessary. This will be determined upon the soil analysis performedfor each site.

|

|

|

Ribbed steel reinforcement for ground beams will be placed in the canals excavatedaccording to the project. The stirrups should be tied to rebar’s by steel wire at every joint.Once all steel is in position, wood or steel formwork will be placed and securely fitted toplace, in situ concrete will be poured. Levelling and smooth finish of concrete will be ensured. |

|

|

|

|

|

|

Prefabricated structure may be designed to stay on concrete blocks instead of reinforcedconcrete foundation. This method preferred where no environmental footprint is asked and building will serve inmultiple location during its life-cycle. Building will be manufactured with base chassis to stay on concrete cubes. |

|

|

|

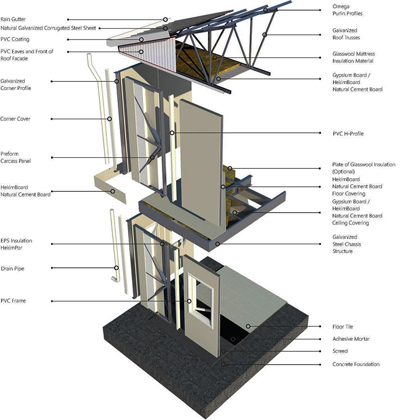

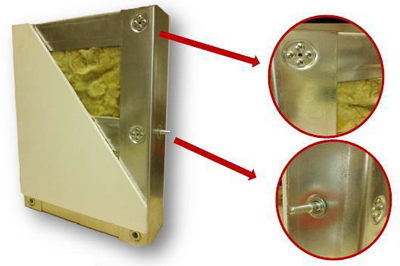

Wall panels consist of fibercement sheets on both sides of galvanized steel sheet skeletonsystem and insulation layer in-between. Insulation layer will be either EPS or mineralwool according to climate condition. | |

|

Thickness of fibercement and skeleton thickness will be chosen specifically according tostructure properties. Panels will be connected to eachother via unique connection system developed forprefabricated structures. PVC-H Profiles will be used between wall panels. Clean water piping, conduit for electrical cables, socket bases and other required infrastructreare in built in wall panels. |

|

|

|

Project specific manufactured galvanized steel profiles in cold forming line will be used forconnection to concrete and each other. All wall panels designed as load-bearing elements. Steel profiles will be used as column andbeams according to structural calculations where wall panels are not available and buildinghaving large openings. |

|

| Roof trusses will be manufactured according to structural calculations with considerataion ofease of transportation and one piece can be lifted & connected. Likewise the rest of the structure, all connection ppoints of roof truss and wall panels are mechanical. Vertical and horizontal crosses will be used for structural rigidity. Roofing purling & eaves, rain gutters, roofing sheets, membrane layer and trapeze sheet willcomplete roof section. |  |

|

|

Rockwool Suspended Ceiling or Fibercement Inverse Ceiling application will be doneaccording to structure properties. Hospital grade anti-bacterial PVC flooring with cove for easy cleaning will be used forflooring. Ceramic flooring and wall will be used for wet surfaces. | |

|

||

| Please fill out the contact form for more details. | ||